Strengths of Pre-Tech

Cutting-Edge Research and Development System

It is essential to develop and commercialize products with high technologies at a fast pace in order to maintain and expand strong competitiveness in the semiconductor wafers and devices, photo masks as well as liquid crystal fields, in which technological innovation occurs at a breathtaking rate. Pre-Tech reinforces research and development through joint efforts of high technology company, thereby obtaining extremely advanced technological support to advance its development of new products based on cuttingedge technologies and theories.

Production System to Maximize Customer Satisfaction

Pre-Tech has competitive edge in customized production based on customers’ specifications and supports the product life cycle from design to development, assembly, inspection, installation, and maintenance. Pre-Tech assesses problems and technical trends from the customer’s perspective by establishing close relationships with the customer at each process level, and promptly starts development accordingly. Many of Pre-Tech’s customers are top companies in their diverse fields, and they are likely to demand high quality standards. Pre-Tech’s design, development, and production divisions work together to meet their high demands, enabling levels of competitiveness fit for a top manufacturer to be developed and maintained. Pre-Tech provides comprehensive customer-focused service to deliver prestigious products using cutting-edge technologies.

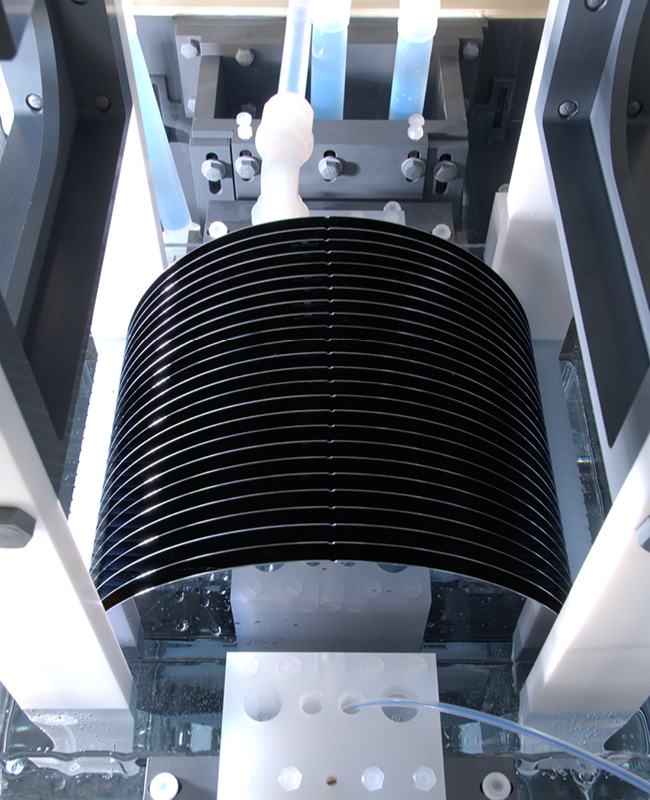

Technology to Produce "Ultra" High Quality

In the production of precision cleaning equipments, high technology is necessary to obtain high cleaning performance and high reliability. In the products that Pre-Tech provides, high elemental technologies are combined and integrated. For instance, batch cassette-less cleaning equipment removes sub-micron particles in semiconductor wafers. In the state-of-the-art systems where this ultra-cleaning technology is applied, the all technologies must be of the highest world standard: whether they are ultrasonics, cleaning processes, or design and control technologies. The system provides various solutions, including high cleaning effectiveness, reduction in the amount of water and chemical solution used per unit area, less power consumption, fewer processes and shorter cycles, and smaller footprints for equipments, achieving both improvements in factory production efficiency as well as reduction of environmental impact.

Control Technology

Careful handling is required for silicon wafers. Direct handling without using cassettes is achieved by highly-accurate mechanical control technology, enabling advanced cleaning.

Piping Technology

As the result of long years of research, we have improved the reliability and functionality of Teflon piping which is necessary for cleaning silicon wafers, providing a high-performance cleaning system.

Process Technology

We have established a system that can provide optimum and highly effective cleaning technologies in line with diversified cleaning processes in various precision cleaning application fields.