Fine-Sonic System

Submicron Particles Can Be Removed at

High-Frequencies - 800 kHZ - 3.0 MHz -

Without Any Damages

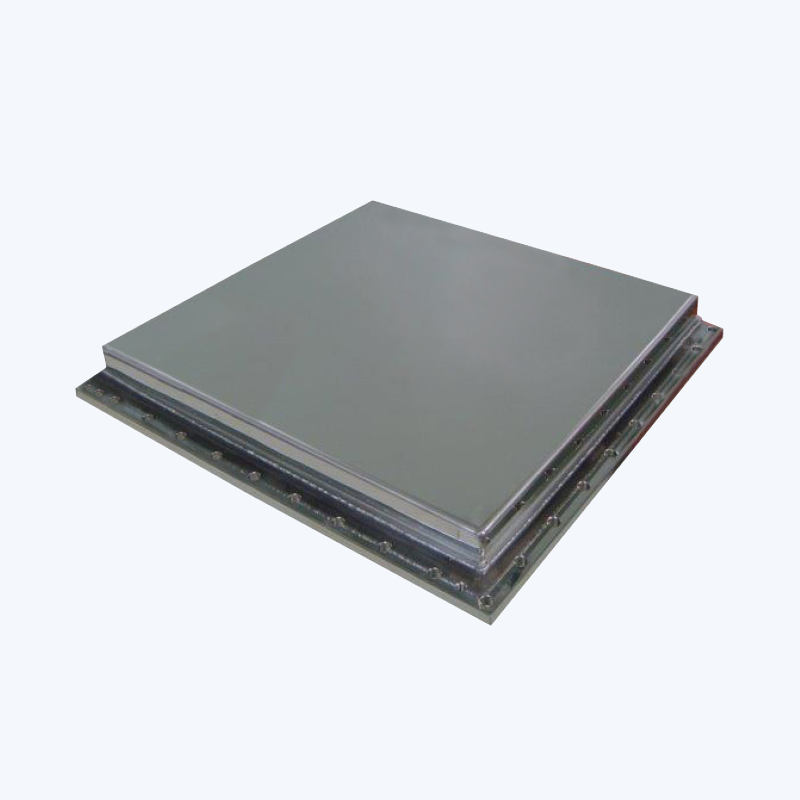

FINE-SONIC

PT-150MV

PT-075MV

Transducer

Features & Applications

Batch-processing cleaner with frequency of 750kHz.

Capable of removing submicron particles without any damage onto a work through efficient sonic-transmission by specific devices.

Most suitable for cleaning Silicon wafers, photo mask and magnetic disks.

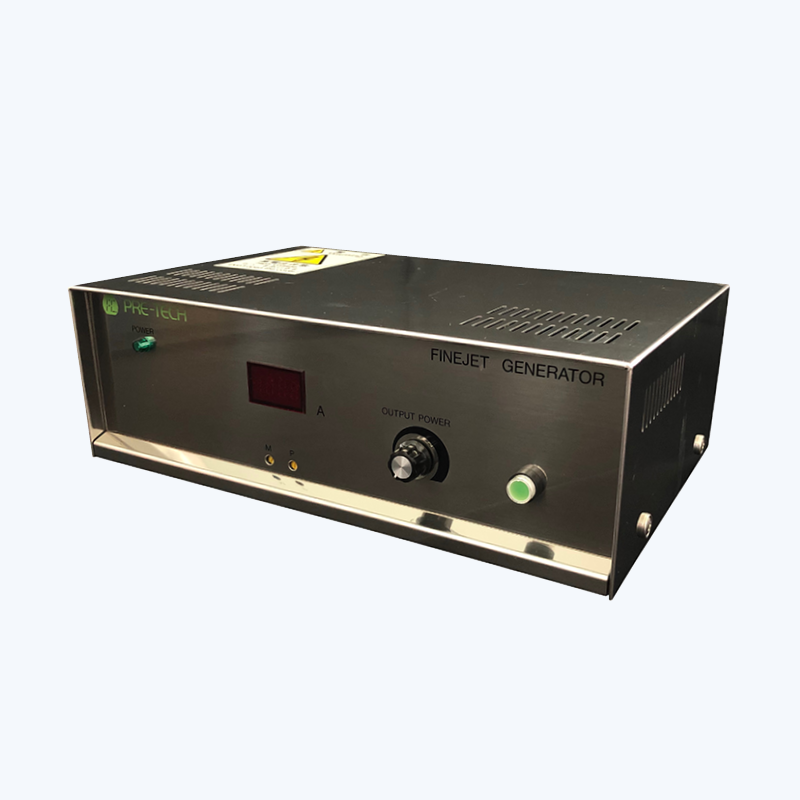

FINE-JET

PT-005J20

PT-010J50

Quartz Nozzle

Features & Applications

Cleaning by spraying Dl water with 400kHz 1.5MHz or 3.0MHz high-frequency sonic through 4Φ nozzle.

Able to clean wafers at the flow rate of 0.8L to 1.5L per minute. Cleaning in the air avoids re-contamination in a cleaning bath and removes submicron particles.

Most ideal for cleaning Silicon wafers, photo mask, LCD glass, magnetic disks, and also usable for cleaning after CMP and single wafer cleaning.

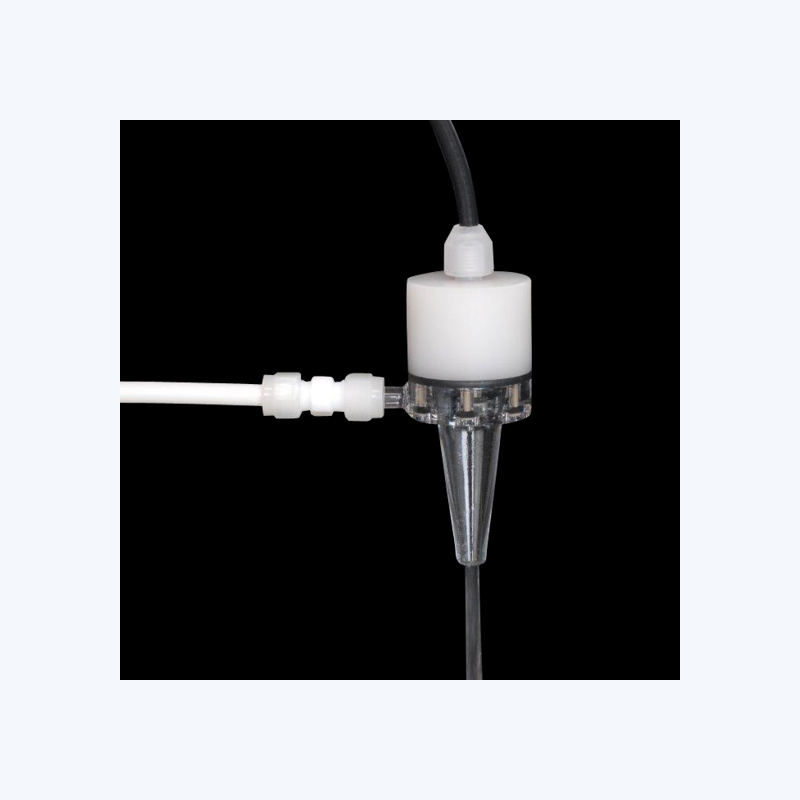

FINE-SQUALL

PT-075MV

PT-075MH

Nozzle

Features & Applications

Cleaning by spraying Dl water with 1.5MHz sonic wave through a nozzle of 2mm width. Cleaning area is configurable to meet the work size 250mm up to 2,210mm.

Bar type cleaning system removes submicron particles with high throughput.

Applicable to large size glass substrate such as TFT & CF. Mountable on the single wafer cleaning system.

Longer size models for the next generation are under development.